Trusted company that deals in quality-made products

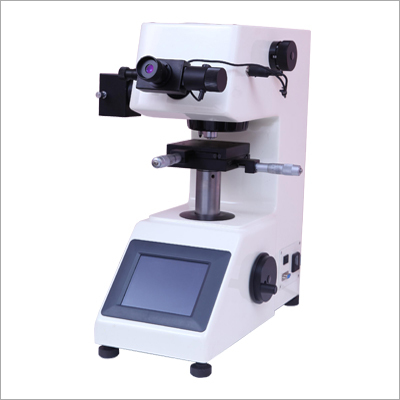

Semi-Automatic Microhardness Tester

600000.00 - 1000000.00 INR/Number

Product Details:

- Display Type LCD Digital Display

- Application Material hardness testing, Laboratory

- Operating Voltage 220 V 50 Hz

- Interface Type USB, RS232 (optional)

- Power Supply Electric

- Product Type Microhardness Tester

- Measuring Range 5 2000 HV

- Click to view more

X

Semi-Automatic Microhardness Tester Price And Quantity

- 600000.00 - 1000000.00 INR/Number

- 1 Number

- Built-in microscope with 10x/40x objectives

- LED illumination for microscope

- Digital printout and PC connectivity

- Vickers/Knoop indentation

- 10 g 1 kg (selectable loads)

- Compatible analysis software included

- Multi-language menu

Semi-Automatic Microhardness Tester Product Specifications

- Microhardness Tester

- 5 2000 HV

- Microhardness (Vickers or Knoop)

- 220 Volt (v)

- 1 per test

- 0.05 0.5 mm/s (adjustable)

- LCD Digital Display

- Material hardness testing, Laboratory

- Up to 100 mm

- Semi-Automatic (manual and automatic selection)

- Approx. 40 kg

- 220 V 50 Hz

- USB, RS232 (optional)

- Electric

- High precision digital measurement, automatic loading/unloading, data storage

- Standard port for optical connection

- Benchtop

- 3% FS

- 50 Hz

- 120 mm (sample height)

- < 2 s

- 10C 35C (operating)

- Semi-Automatic Microhardness Tester

- 30 mm

- 0.1 HV

- 85% RH (non-condensing)

- Laboratory

- 5 2000 HV

- White

- Semi-Automatic

- Single sample per cycle

- Maximum 100 x 100 mm

- Built-in microscope with 10x/40x objectives

- LED illumination for microscope

- Digital printout and PC connectivity

- Vickers/Knoop indentation

- 10 g 1 kg (selectable loads)

- Compatible analysis software included

- Multi-language menu

Semi-Automatic Microhardness Tester Trade Information

- Pune

- 3 Number Per Month

- 4 Week

- All India

Product Description

Semi-Automatic Microhardness Tester

- Load Range - 10 gm to 1 kg; 5 gm and 1 gm optional

- Auto Turret - 3 position or 6 position

- Motorized Loading

- LCD touch screen panel to select load, turret position, illumination, display of diagonal lengths, hardness value etc

Specification

|

Dwell Time |

5 - 95 Seconds |

|

Test Load |

10-1000 gf |

|

Voltage |

230 V |

|

Brand |

Conation |

|

Automation Grade |

Semi-automatic |

|

Load Capacity |

5 gm,2 Kg,3 Kg,5 Kg |

|

Display Type |

LCD Touch Screen |

Advanced Optical System for Precise Analysis

Equipped with a built-in microscope utilizing 10x and 40x objectives, the tester delivers sharp imagery and accurate indent measurements. The LED illumination ensures consistent lighting, vital for reliable observation and analysis results. This sophisticated optical system enhances precision in microhardness testing, enabling reliable data collection for laboratory applications.

Efficient Digital Data Output and Connectivity

This microhardness tester incorporates digital printout capabilities, standard USB interface, and optional RS232 connectivity, making data transfer and reporting straightforward. Integrated multi-language menu and included analysis software simplify workflow, while automatic storage of measurement data supports comprehensive records for ongoing research and quality control.

Flexible Testing Modes and Load Selection

With semi-automatic control, users can select between manual and automated test cycles, facilitating a tailored approach to specimen evaluation. The selectable load range from 10 g to 1 kg provides versatility for testing various materials, supported by adjustable test speeds and strokes to suit specific laboratory needs and sample requirements.

FAQ's of Semi-Automatic Microhardness Tester:

Q: How does the tester accommodate different sample sizes and materials?

A: The microhardness tester is designed for single samples up to a maximum size of 100 x 100 mm and height of 120 mm. By featuring selectable loads (10 g - 1 kg) and adjustable test width (up to 100 mm), it efficiently adapts to a variety of material types and thicknesses encountered in laboratory environments.Q: What software and data output options are provided with this equipment?

A: This tester comes with compatible analysis software to facilitate easy data processing. Digital printout, USB interface, and optional RS232 port allow measurements to be exported to a PC for detailed reporting, documentation, and record-keeping. Multi-language menu ensures accessibility for diverse users.Q: When should I use the automatic versus manual testing modes?

A: Automatic mode streamlines routine hardness testing, reducing manual intervention and boosting throughput. Manual mode is recommended when custom control over the measurement process is needed, such as for research on unique sample types or for troubleshooting specific testing scenarios.Q: Where is this instrument ideally used?

A: The Semi-Automatic Microhardness Tester is best suited for laboratory environments specializing in material hardness testing, including research institutions and quality control laboratories. Its precision and flexibility make it a valuable asset for metallurgical, manufacturing, and academic laboratories in India.Q: What is the typical process for performing a Vickers or Knoop hardness test using this equipment?

A: Begin by preparing the sample and mounting it securely. Select the desired load and test mode. Use the built-in microscope with LED illumination to focus on the test area, then initiate indenting. After the test, the instrument measures indentation and digitally displays results, which can be recorded or exported for analysis.Q: How does the equipment ensure reliable and accurate measurement results?

A: With high-precision mechanics, automatic loading/unloading, and a resolution of 0.1 HV, results are both consistent and accurate. The tester's accuracy is 3% FS, and the built-in microscope enables clear indent observation. Combined with stable operating conditions and thorough software analysis, this ensures dependable hardness data.Q: What are the benefits of using this semi-automatic microhardness tester?

A: This instrument offers high-efficiency measurements, reduced operator fatigue, reliable test repeatability, and versatile application to a wide range of materials. Its digital data output, multi-language support, software compatibility, and refined optical system streamline laboratory workflows and improve testing accuracy.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free