Trusted company that deals in quality-made products

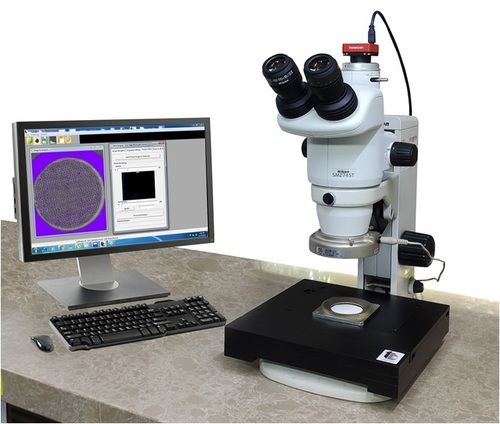

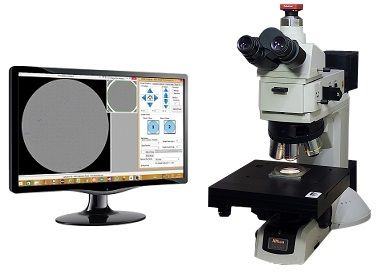

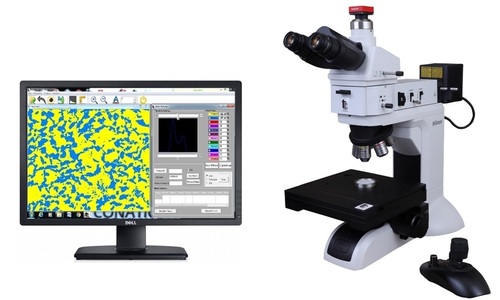

Metallography analysis system

12,00,000.00 - 25,00,000.00 INR/Number

Product Details:

- Color White

- Voltage 220 Volt (v)

- Usage Laboratory

- Product Type Metallography analysis system

- Theory Metallurgical Microscope

- Drawtube Trinocular

- Sensor Optical

- Click to view more

X

Metallography analysis system Price And Quantity

- 12,00,000.00 - 25,00,000.00 INR/Number

- 1 Number

Metallography analysis system Product Specifications

- Metallurgical Microscope

- 220 Volt (v)

- White

- Laboratory

- 50X-1000X

- Trinocular

- Metallography analysis system

- Optical

- Halogen or LED

- USB2.0

Metallography analysis system Trade Information

- 3 Number Per Week

- 2 Week

- All India

Product Description

Fully Automatic Metallurgical Microscope

Fully automated Metallurgical analysis system that include high resolution metallurgical microscope, high precision motorized XY scanning stage, motorized (auto) focusing, high resolution camera and advanced image analysis software compatible to motorized microscope

Magnification - 50X to 1000X

With Polarizer and analyzer

Option for Darkfield and DIC

High-Resolution Metallurgical Imaging

This system delivers sharp and accurate images of metal structures thanks to its premium optical sensor and magnification range of 50X to 1000X. The combination of halogen or LED illumination ensures precise visualization, enabling effective microstructural investigations essential in materials science.

Seamless Data Handling and Ergonomics

Equipped with a USB2.0 interface and a convenient trinocular drawtube, transferring and sharing digital images for analysis is straightforward. The ergonomic design supports extended laboratory work, enhancing user comfort and analytical accuracy.

FAQ's of Metallography analysis system:

Q: How is the metallography analysis system typically used in laboratories?

A: The system is predominantly employed to examine and document the microstructure of various metal samples, aiding in quality assurance, failure analysis, and research developments within laboratory environments.Q: What magnification options are available, and how do they benefit analysis?

A: This system provides a versatile magnification range from 50X to 1000X. Such options enable detailed inspection of metallurgical features, from general grain structure to intricate inclusions, enhancing analytical depth and reliability.Q: When should one use halogen versus LED illumination in this system?

A: Halogen illumination is preferred when color accuracy is crucial, while LED is ideal for energy efficiency and longer operational life. Users can select the source that best matches their specimen's requirements and analysis goals.Q: Where can this metallography system be installed and operated efficiently?

A: It is designed for laboratory settings, especially within research institutes, industrial quality control departments, and academic institutions across India, requiring only a standard 220V power supply.Q: What is the process for capturing and storing images with this system?

A: After preparing and positioning the sample, users can observe the specimen through the trinocular drawtube and capture images digitally via the USB2.0 interface, allowing efficient storage and further analysis.Q: Why is there a benefit to using an optical sensor and trinocular configuration in metallurgical studies?

A: The optical sensor delivers superior image fidelity, while the trinocular drawtube supports simultaneous visual and digital observations, streamlining collaborative research and documentation tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email