Trusted company that deals in quality-made products

Fully automated Cleanliness Particle Analysis

1200000.00 - 2200000.00 INR/Number

Product Details:

- Voltage 200-220 Volt (v)

- Product Type Fully automated Cleanliness Particle Analysis

- Color White

- Usage Lab

- Theory Metallurgical Microscope

- Drawtube Binocular

- Click to view more

X

Fully automated Cleanliness Particle Analysis Price And Quantity

- 1 Number, ,

- 1200000.00 - 2200000.00 INR/Number

Fully automated Cleanliness Particle Analysis Product Specifications

- Fully automated Cleanliness Particle Analysis

- White

- 200-220 Volt (v)

- Metallurgical Microscope

- Lab

- Binocular

Fully automated Cleanliness Particle Analysis Trade Information

- Pune

- 3 Number, , Per Month

- 4 Week

- All India

Product Description

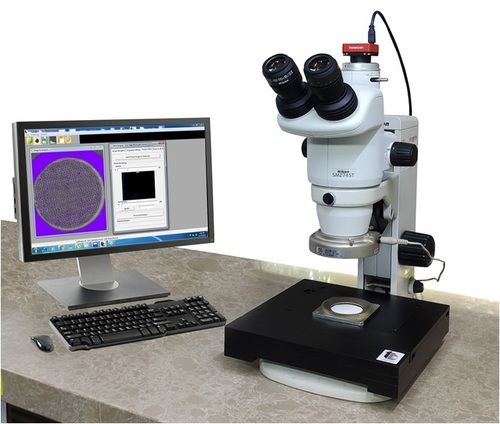

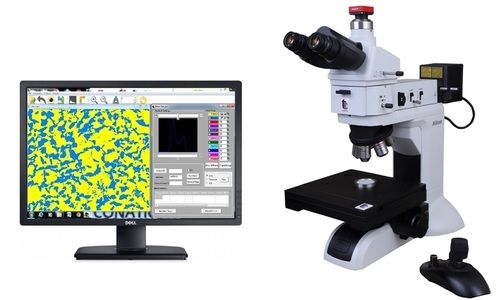

Automatic (Motorized) Particle Analysis System

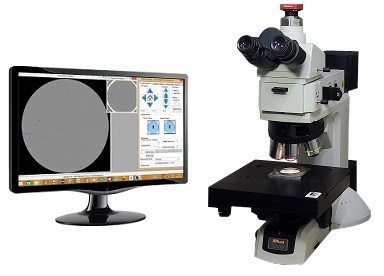

Fully automated Particle Analysis system consists of high resolution optical microscope, motorized XYZ scanning stage, German made high resolution camera and full loaded particle analysis software as per ISO 16232-18, VDA 19.1 and ISO 4406

Optical Microscope - Nikon make with 50X to 200X magnification (expandable upto 1000X)

5 MP Germany made camera

Precision Motorized scanning stage for scanning the entire filter paper

Motorized focusing

DeXel-Filtrate software to count all the particles on filter paper, size measurement of each particle, distribution into metallic, non-metallic and fibre

Reliable Automated Particle Analysis

Our system provides a completely automated solution for particle cleanliness analysis. By streamlining workflows, laboratories can ensure greater accuracy and repeatability in detecting and quantifying particulate contamination. The automation significantly minimizes human error and allows for efficient sample processing, supporting quality control in metallurgy and related industries.

Designed for Laboratory Precision

Equipped with a binocular drawtube and operating on a stable 200-220 volt power supply, this system seamlessly integrates into laboratory environments. Its compatibility with metallurgical microscopes ensures high-resolution imaging and comprehensive analysis, making it ideal for detailed cleanliness assessments in critical applications.

FAQ's of Fully automated Cleanliness Particle Analysis:

Q: How does the fully automated cleanliness particle analysis system operate?

A: The system operates by integrating with a metallurgical microscope and using automated software to capture and analyze images of samples for particulate contamination. Once samples are loaded, the automation manages both scanning and quantitative analysis, requiring minimal manual intervention.Q: What are the key benefits of automating particle cleanliness analysis in laboratories?

A: Automation provides consistent, accurate results while reducing chances for human error. It increases efficiency by handling large volumes of samples faster and offers standardized reporting, essential for quality control and regulatory compliance in industries like metallurgy.Q: When should a laboratory opt for a fully automated cleanliness analysis system?

A: Laboratories should consider this system when there is a need for high-throughput, reliable, and repeatable particle analysis. It is especially beneficial when precise contamination assessment is crucial for quality assurance or process control in manufacturing or research.Q: Where can this particle analysis system be installed?

A: This instrument is designed for laboratory use and can be installed on standard lab benches where a stable power supply of 200-220 volts is available, making it suitable for research labs, industrial quality control departments, and academic institutions.Q: What is the process of using the automated cleanliness analysis system?

A: The typical process involves preparing sample slides, placing them under the microscope, and letting the automated system scan and analyze the particles present. The system generates detailed reports, including images and particle counts, for thorough review and documentation.Q: How does the binocular drawtube enhance usability for laboratory personnel?

A: The binocular drawtube allows comfortable, ergonomic viewing for extended periods, which helps users inspect images directly if needed, supporting both manual review and automated verification during the analysis process.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email