उत्पाद विवरण

Weld structure analysis is extremely important to understand the quality of the weld, which in turn helps to understand the strength, performance and durability of the welded component. Any kind of weld such as butt weld, lap weld or T-joint weld should pass through the stringent macrographic inspection to reveal the intended quality, anomalies or disparities.

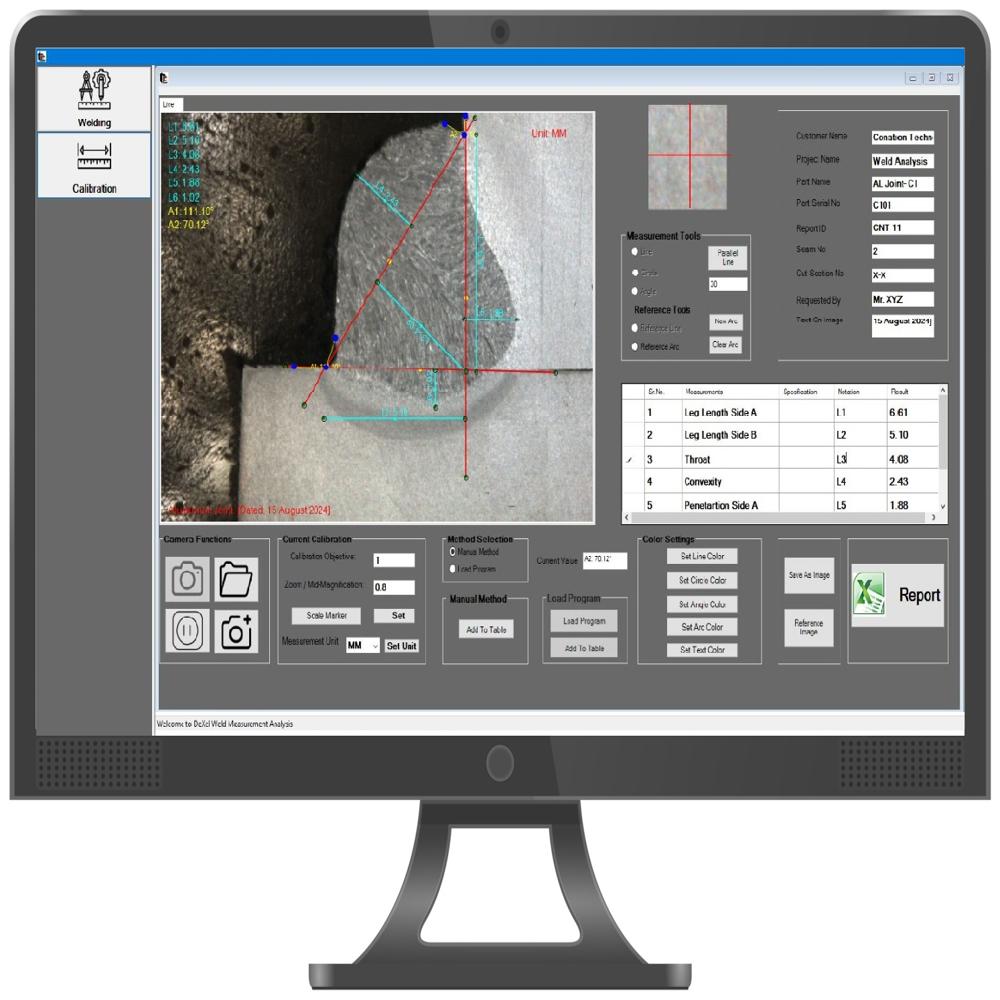

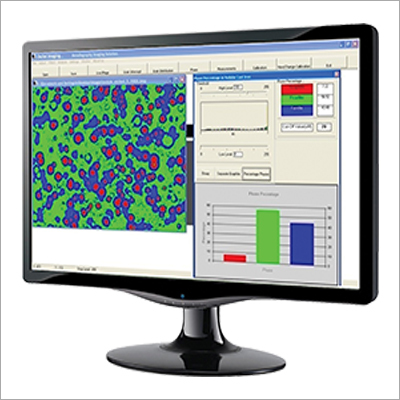

Similar to metallography analysis, weld joint need to be cut in cross-sectional direction, polished to the mirror finish and etched with appropriate etchant to reveal the structure of bead, surrounding area, heat affected zone, weld passes etc. This sample then is placed under stereozoom microscope and further analysis can be carried out with DeXel-Weld Image analyzer.

Advanced Weld Analysis Made SimpleDesigned with user-friendly digital display panels and a secure operation system, the Weld Penetration Analyzer streamlines the process of inspecting welds. Its automated inspection support allows for efficient and consistent results, making weld analysis suitable even in demanding industrial environments.

Versatile and Non-destructive TestingCompatible with steel and stainless steel, the analyzer employs a non-destructive detection method. This ensures weld integrity is never compromised during to assessment. The analyzer's compact dimensions and lightweight design allow easy integration into existing industrial workflows.

FAQ's of Weld Penetration Analyzer:

Q: How does the Weld Penetration Analyzer identify weld penetration without damaging the material?

A: The device employs a non-destructive technique to evaluate weld penetration, enabling precise analysis without altering or harming steel and stainless steel surfaces during inspection.

Q: What is the process for using this analyzer with welding machines?

A: Connect the analyzer to your welding machine and initiate automated inspection through the digital display panel. The LED indicator presents real-time results, allowing for prompt assessment of weld quality.

Q: When should you use the Weld Penetration Analyzer in industrial operations?

A: It is best utilized during or after welding processes to verify penetration depth, ensuring every weld meets stringent quality standards before proceeding to the next fabrication stage.

Q: Where can this analyzer be applied within the industry?

A: It is suitable for use in manufacturing plants, fabrication workshops, or any industrial setting that involves welding work on steel or stainless steel components.

Q: What security features are included in the Weld Penetration Analyzer?

A: Protected operation circuitry safeguards the device and its user, minimizing risks associated with electrical malfunctions or inadvertent usage.

Q: What are the main benefits of using a Weld Penetration Analyzer with automated inspection support?

A: Automated inspection increases efficiency, reduces human error, and provides reliable, repeatable results, ensuring weld integrity and consistent production quality.

Q: Is the analyzer easy for a single operator to handle in day-to-day industrial use?

A: Yes, its lightweight construction, straightforward digital interface, and single-person capacity make the analyzer simple to operate and integrate into routine industrial weld analysis.

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें